Coating

& lamination

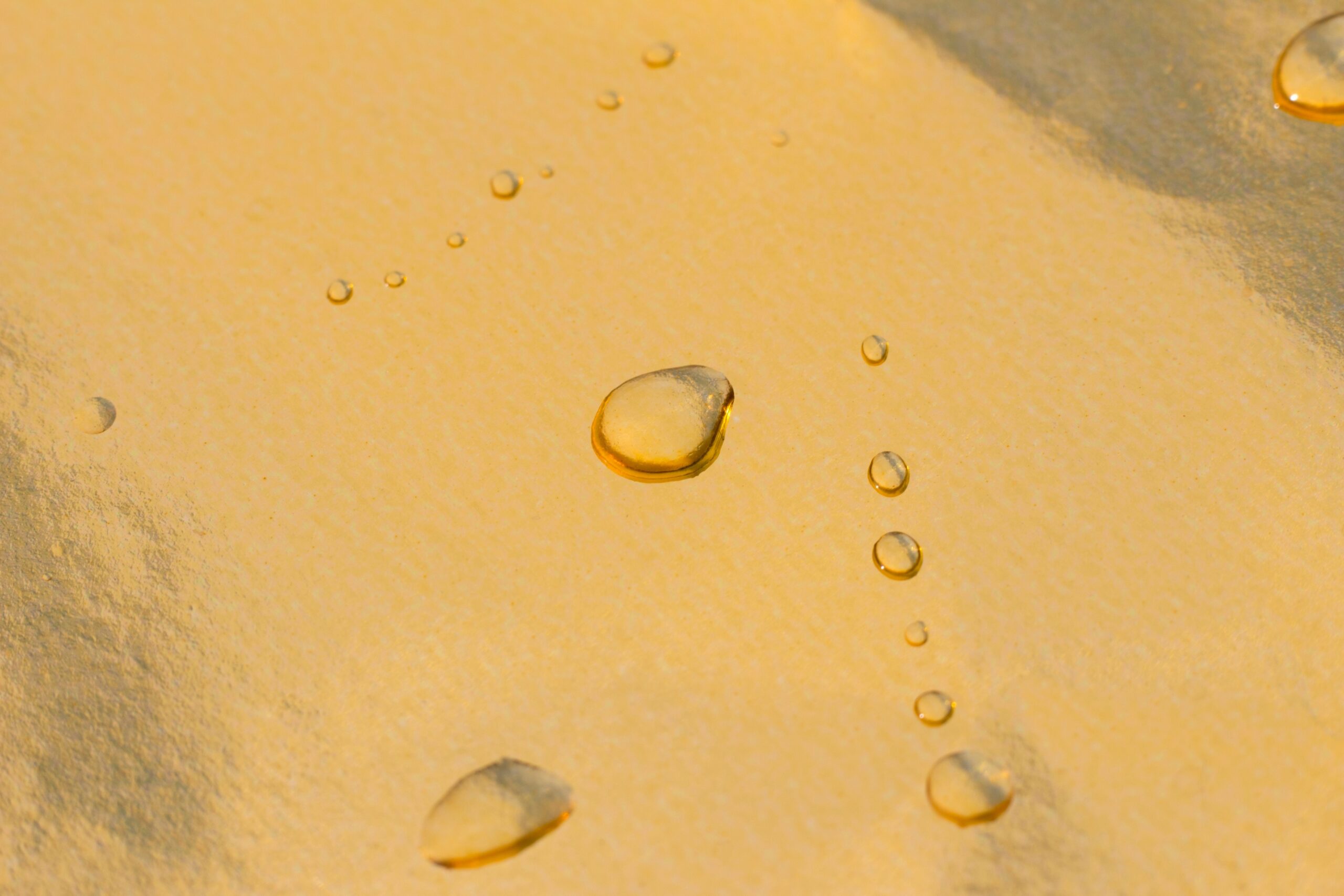

Coating or laminating paper and board improves the longevity, aesthetics and functionality of packaging. Adding a protective layer strengthens the material and provides protection from external elements, in many cases extending the shelf life of the product in the packaging. In addition to improving the physical properties of the material, it also plays an important role in branding.

Thanks to the versatility of coating and lamination, we offer customized solutions for specific requirements and wishes. IPP works with a number of parties who provide excellent finishing services.

1.

In lamination, layers of material are joined into one. For example, a film that adheres to the base material through thermo-lamination, or a gold paper that is applied to a backing by glueing. By laminating paper, cartonboard or foil, you make it resistant to tearing or perforation. And you can make it moisture- and grease-resistant and freezer- or heat-resistant. There are also decorative laminates, such as gold, silver, hologram, matte and textured.

2.

Through coating and extrusion, we improve the barrier properties of paper and board. During an extrusion process, a thin liquid coating is applied that makes the material grease- and moisture-resistant, sealable, stronger, freezer- or heat-resistant, among other things.

"*" indicates required fields